PRODUCTS

activated carbon in gold recovery

1.How about the sample?

we can provide offer free samples and freight charges is collected

2.what is your MOQ?

our product MOQ is 10kg

3.what kind of package will use?

25kg/bag, 500kg/bigbag,or according to customer's requirements.

Gold recycling process

To recover gold, water and a cyanide such as calcium, sodium or potassium cyanide are added to ore or waste to form a slurry.

The gold is leached out and mixed with cyanide into solution. Activated carbon is then used to separate and store the gold before it is removed as the final step in the process.

Modern gold recycling uses three basic operating systems.

Carbon in pulp: Carbon in pulp (CIP) processing occurs when leaching is performed in stirred tanks prior to the introduction of activated carbon.

Leached carbon: Leached carbon, or CIL, occurs when activated carbon is added to the slurry before leaching occurs. Gold is simultaneously leached and adsorbed.

Carbon in Columns: Carbon in Columns (CIC) is a completely different process. After leaching, the gold cyanide solution is poured into a giant column filled with activated carbon.

Each operating system has its own strengths and weaknesses, but in the end they all serve the same purpose: making money.

Why Use Activated Charcoal?

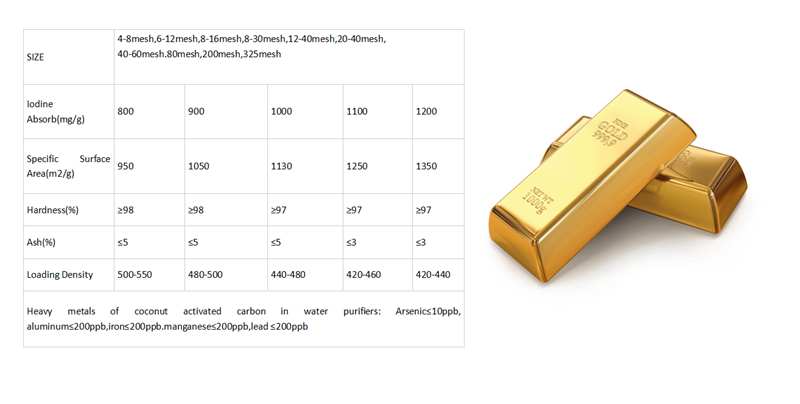

Activated carbon has amazing adsorption capacity. The activation process produces a microscopically porous network with a large surface area that provides numerous attachment points for gold molecules. These molecules are attracted to the activated carbon surface molecules and then reach the activated carbon for desorption.

What happens to used activated charcoal?

Activated carbon is considered "used" once the gold recovery process is complete. However, re-use is allowed. Some recycling operations can reactivate their own carbon, but many prefer to send their used carbon to professionals for reactivation.